1. Material

New type of stainless steel with outstanding corrosion resistance

New STS400 steel material containing molybdenum (Mo)

Shows powerful corrosion resistance with less generation of rust due to chlorine gas

2. Technique

Bolt assembly, panel joint technique

Completely eliminates the issue of rust generation thanks to a non-welding bolt assembly technique

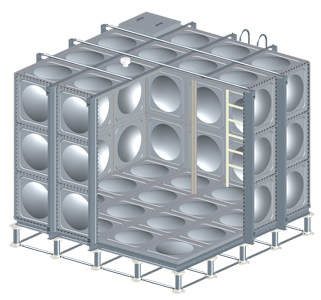

3. Structure

System that emphasizes external reinforcement

Minimized internal horizontal reinforcing materials by employing the external frame reinforcement method

1-3mh: 100% external reinforcement type (no internal reinforcing materials)

Greater than 3.5mh: Internal and external mixed reinforcement type (no reinforcing materials on the upper section)

Increased sanitation and convenience in cleaning

4. Comparison of corrosion resistance characteristics

| Category | Characteristics of STS400 | Characteristics of STS300 |

|---|---|---|

| Impurities | Minimum amount having no effect on structural steel | Small amount having some effect on structural steel |

| Processability | Fair to weak | Excellent |

| Welding deformation | Excellent (less deformation) | Weak (significant effect of welding heat) |

| Corrosion | Excellent (no effect on chlorine ion) | Weak (vulnerable against chlorine ion) |

| Magnetism | Magnetic material | Non-magnetic material |

| Grain boundary | Ferrite stainless steel | Ostenitic stainless steel |

| Stress corrosion | Very excellent | Weak |

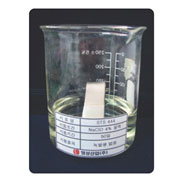

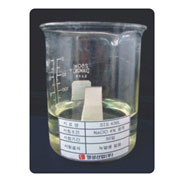

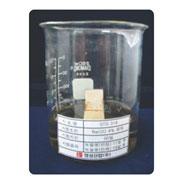

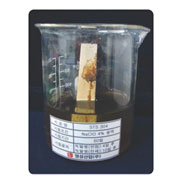

5. Chlorine immersion test

- Test solution: 4% chlorine solution, Test period: 50 days

STS444

NO RUST (50days)

STS436L

NO RUST (50days)

STS316

Rust occurred(a bit):

after 11day

Rust occurred(entire):

after 19day

STS304

Rust occurred(a bit):

after 4day

Rust occurred(entire):

after 10day

Facebook

Facebook