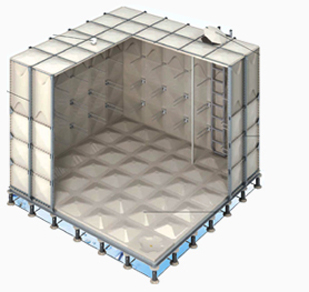

1. GRP Water Tank Features

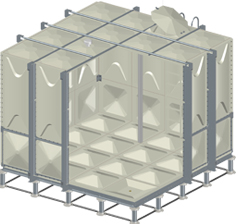

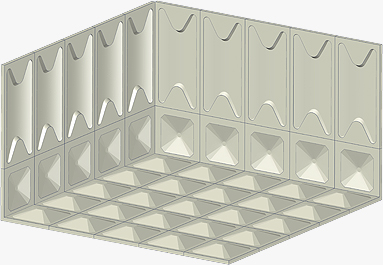

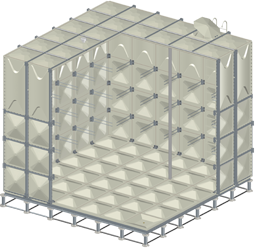

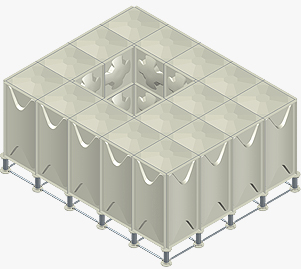

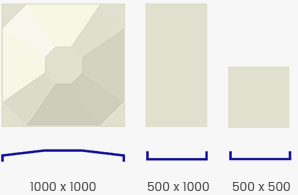

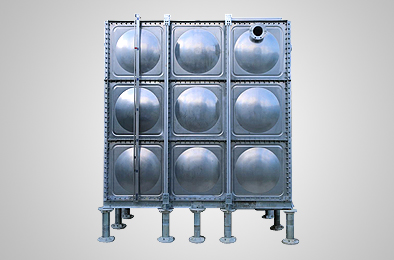

Design in various capacities

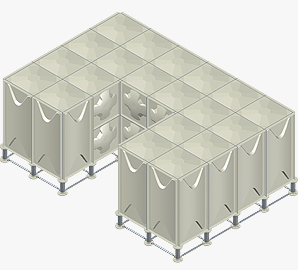

Panels in various sizes and shapes feature structures that maximize utilization of the capacity and horizontal and vertical installation spaces, thus sufficiently satisfying customer requirements. Use of such a variety of panels enables the installation of l-shaped, c-shaped and square-shaped water tanks, as well.

Superior Sanitation

Conforming to the regulations of the Food Sanitation Act, GRP panels completely block off the light to prevent the proliferation of bacteria and various germs, while the high-temperature molding process allows for a beautiful surface and hardness that promotes a material resistant to corrosion. Also, any raw materials designated as being potentially harmful in generating endocrine disruptors are not used during GRP production, making them harmless to the human body.

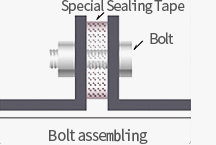

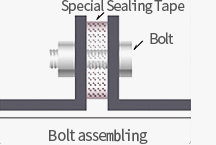

Perfect Water Tightness

It possesses perfect water tightness by using special sealing materials with outstanding weatherproof properties and restitution.

Strength & Durability

Advanced GRP complex materials maintain the highest water pressure resistance thanks to high-temperature, high-pressure press molding, and the internal structures of the water tank have applied STS (stainless steel), while the external structures have been processed with hot-dip galvanization for corrosion resistance.

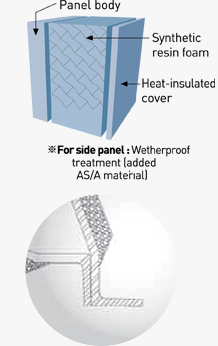

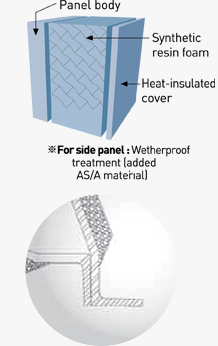

Outstanding Thermal Properties & Condensation Prevention

Three-layered, thermal panels (25 mm, 50 mm), equipped with GRP's own adiabaticity, retain excellent thermal properties.

Excellent Constructability & Transportability

Panels with great dimensional stability reduce the period of construction to enable convenient the transferring or relocation of materials in narrow spaces on site.

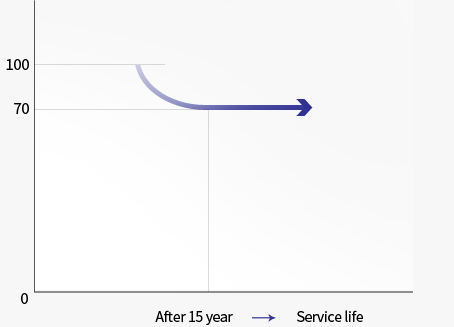

2. Stability - High Quality

Hi Tank pursues an optimal system through quality management with strict design standard and reliable structural stress analysis.

A critical aspect in structural analysis is the design according to safety factor at a threshold level.

Serim’s expertise lies in the design of optimal safety factor considering the expected external forcebased on the Physical properties of the GRP material after long-term use of more than 15years.

Since Hi Tank does not take account of the initial value (100%) of the GRP properties but only considers the minimum value (70%) and safety factor while designing, SERIM Hi Tank guarantees long-term durability.

GRP Degradation Process

Physical properties

Designed external force

Water load in the tank, dead load, snow load,

wind load, live load and seismic load

Design standards

Designed external force > Threshold level ÷ Safety factor

| Item | Guaranteed Load Conditions |

|---|---|

| Earthquake | Horizontal seismic intensity Kh=2/3G |

| Hydrostatic | Water Level(Height in Meters) × |

| pressure | 0.1kgf/cm2(0.01MPa) |

| Snow load | 60kg/m2 |

| Wind load | Below 60m/sec |

| Illumination | Less than 0.1% |

| Water temperature | Cold and hot water is used up to 50℃ |

3-1. GRP Panel - Best Hygienic Properties

With the use of excellent corrosion-resistant panels, the surface of the tank is uniformly smooth without any moss growth and enables long-term use as the panels inhibit the proliferation of bacteria and other various germs by perfectly blocking all the light from outside.

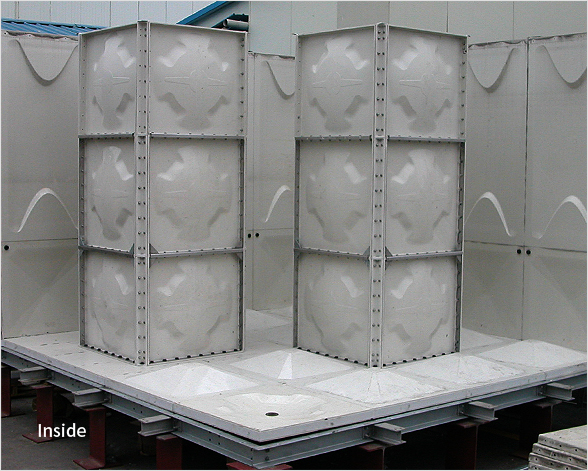

Materials for Reinforced Components

| Inside | for Liquid part | Stainless Steel [STS] |

|---|---|---|

| for Air part | Plastic or corrosion - resistant material | |

| Outside | Steel + hot galvanizing |

As chlorine gas remains in the air area and this may corrupt the SUS and other metals, it is critical that anti-corrosion materials are selected.

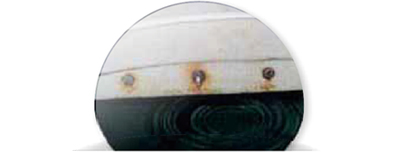

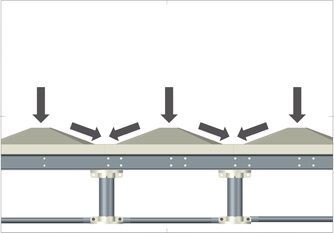

Product with Inferior Hygienic Properties

When light penetrates in the tank

Moss and microorganism grow

When general STS bolts are used

in the air area

Corrosion occurs due to chloride gas

Welded type air area of the STS tank

Corrosion occurs due to chloride gas

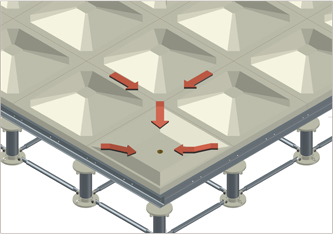

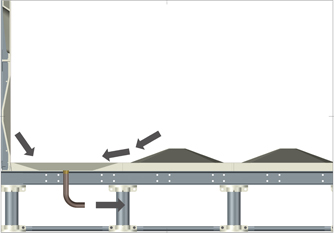

Advantages of Hi-TANK GRP water tank

Hi-TANK GRP water tank uses convex type panels for the base. The convex type panel is designed that any increase in water pressure closes the bottom panels joints and the joints are sealed with a special rubber sealant. And the combination of convex type panels with a concave type drain panel ensures complete and faster drainage and the drain panel was specially designed to facilitate periodic water tank cleaning and inspection.

3-2. Antibacterial Panel - Necessity of Cell Antibacterial Function

Serious contamination by rusting

inside Stain water tank

Water tank installed in places

where direct supply of tap water is not available

Bad water condition

Failure to perform regular cleaning

Propagation of bacteria and algae

Examples of poorly managed tanks

Water tank using only the best material for hygiene improvement

A non-toxic antimicrobial in which a zeolite carrier is substituted with an antibacterial metal (Ag)

Differences from organic antimicrobial

- Stable at high temperature

- No volatility or exudation

- Long-lasting antimicrobial power

Patent registered (Patent No. 0492751)

Results of panel performance evaluation

| Item | Performance standard | Test result | |

|---|---|---|---|

| Mechanical strength | 1) Tensile strength | 60MPa | 86 |

| 2) Flexural strength | Over 80MPa | 191 | |

| 3) Flexural modulus | Over 6000MPa | 13262 | |

| 4) Barcol hardness | Over 30 | 41 | |

| 5) Absorption power | Less than 1% | 0.2 | |

| Exudation of harmful components | 1) Heavy metal | Less than 0.1%ppm | Not detected |

| 2) Consumption of KOn04 | Less than 10ppm | 2.8 | |

| 3) pH | 5.8~8.6 | 7.5 | |

| 4) Phenol | Less than 0.005ppm | Not detected | |

| 5) Evaporation residual oil | Less than 30ppm | 3.2 | |

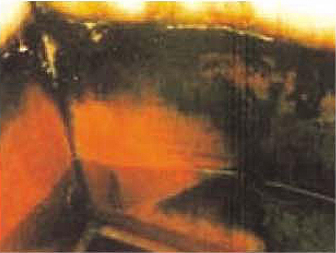

| Antimicrobial power | 1) Escherichia coli | Over 95% | 99.0% |

| 2) Yellow staphylococcus | Over 95% | 99.0% |

Characteristics of antibacterial GRP panel

GRP with inorganic antibacterial

Excellent mechanical strength with reinforced plastic

Hazardous component leaching test pass

Strong antibacterial effect over 99%

Antimicrobial test photo

Performance standard : Conformed to S mark inspection standard (SF-4811-11) of Korea Chemical Testing and Research Institute.

Pathogenic Escherichia coli and Staphylococcus aureus are harmful bacteria causing food poisoning.

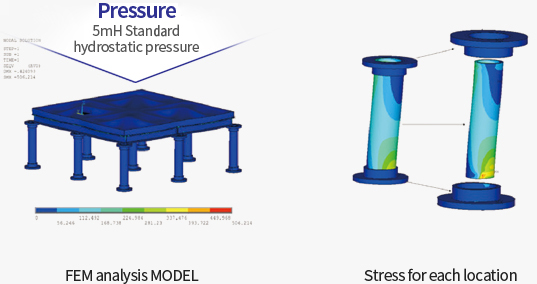

4. Optimal structural design

With years of expertise in structure design, we provide perfect structure safety.

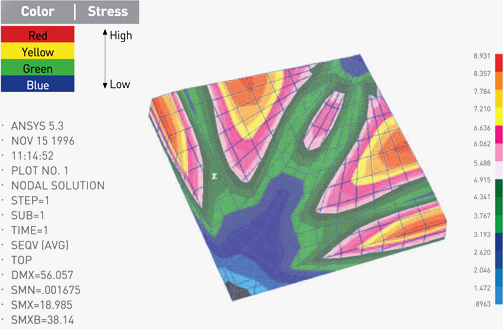

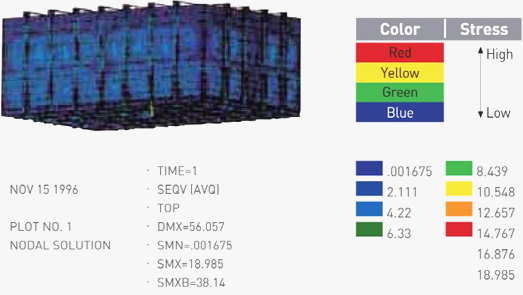

We performed structure analysis by the Finite Element Method to secure reliability on a reinforcement system, the strength of panels and pursue the optimal design. By inputting all possible factors such as hydrostatic pressure, seismic load, snow load, wind load, etc. We estimated the stress and distortion level. Through intensive reinforcement on the part with maximum stress, we aimed to design the best stable system.

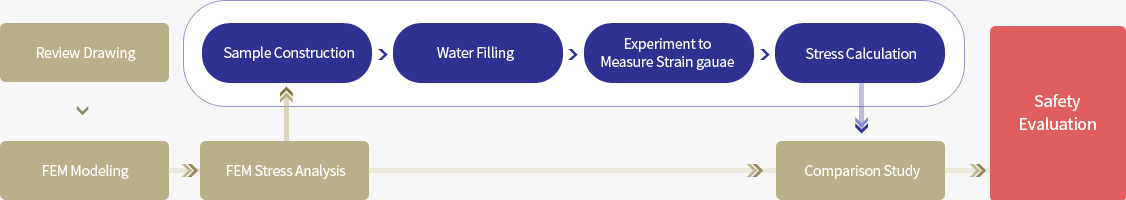

Structure Analysis Flowchart

Stress Analysis of the Panel(FEM)

By modeling the entire system of the basic design, we evaluate the level of stress when inputting loads and find out the part where the maximum stress occur. With repetitive improvement of designing, we establish an optimal system of high reliability.

Long-term Durability Test(Field test)

Generally, there is more than one water depletion and filling up a water tank per day on the average.

Therefore, if the tank is used for 15 years, approximately 4000 times of water circulation would occur and the tank would sustain about 4000 repetitive loads.

Stress Analysis of the Panel(FEM)

By modeling the entire system of the basic design, we evaluate the level of stress when inputting loads and find out the part where the maximum stress occur. With repetitive improvement of designing, we establish an optimal system of high reliability.

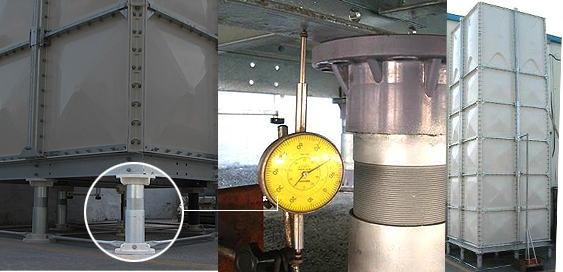

Strain Gauge Test

Long-term Durability Test(Field test)

Generally, there is more than one water depletion and filling up a water tank per day on the average.

Therefore, if the tank is used for 15 years, approximately 4000 times of water circulation would occur and the tank would sustain about 4000 repetitive loads.

Before launching new product into the market, Hi Tank undergoes field tests to check for water leakage and other defects by applying the expected repetitive loads of water circulation to two tanks every day and night for about 6months.

Such tests make us possible to guarantee the safety and durability of Hi Tank.

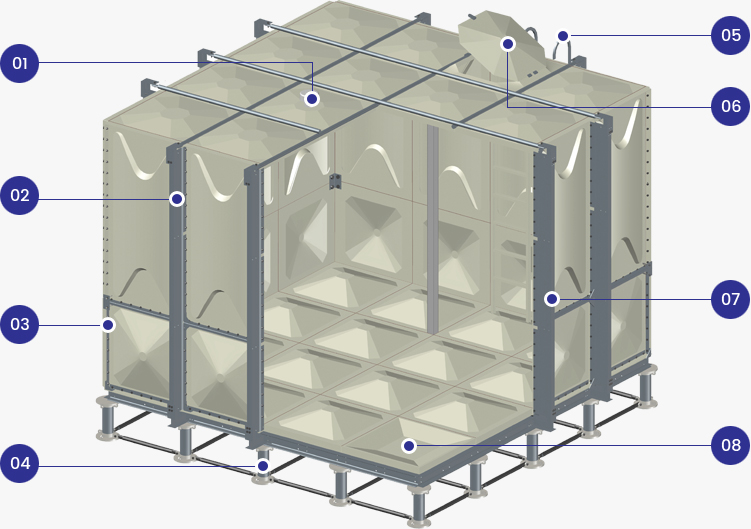

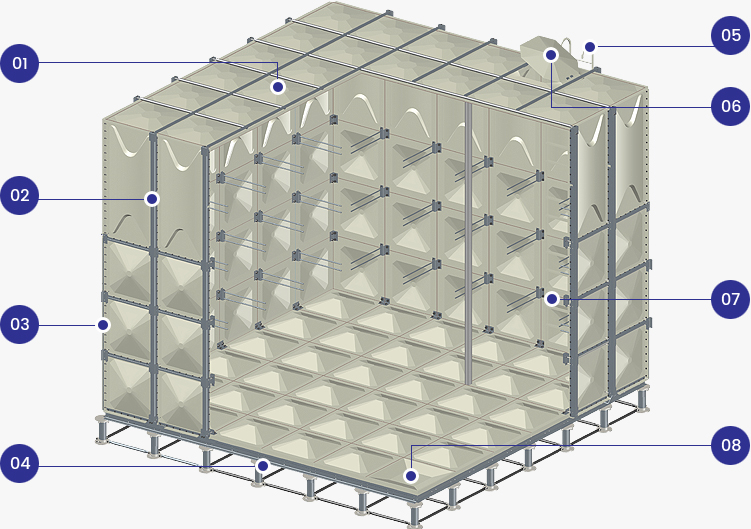

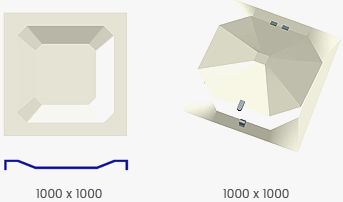

5-1. Variety of Reinforcement Methods

SERIM

HI TANK

External Reinforcement System

01 Air-Vent(ABS)

With PE-mesh insect-guard

02 Water tightness

Maintains perfect water tightness by using sealing tape of PVC foam which is excellent for inhibiting the effects of weathering and for its restorative ability.

03 Outstanding Thermal Effect

Prevents freezing and dew condensation as it demonstrates outstanding thermal effect due to the inherent thermal resistance of the GRP material and polyurethane heat-insulating materials.

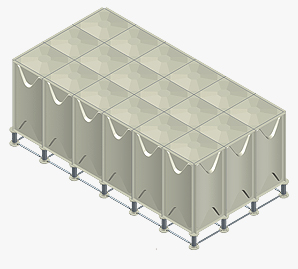

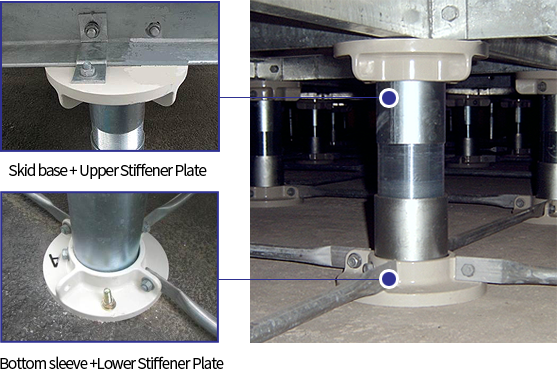

04 Level Adjustable Foundation

Replaces concrete foundation

Allows to make easy and speedy construction

Allows to adjust a very fine tolerance

05 External Ladder

Aluminum

06 Manhole

Convenient & close structure

Mounted special lock

07 Internal Ladder

UPVC

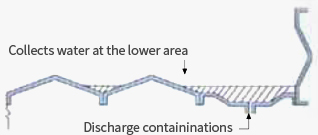

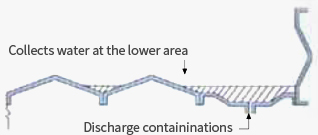

08 Lower Water-discharging Panel Structure at the Bottom Area

Uses lowered drainage panel on the bottom so that it can collect and discharge the water.

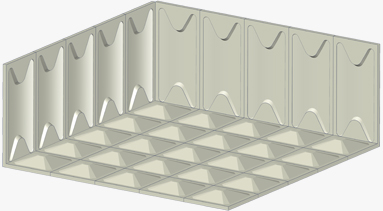

HI TANK OFFERS

External Reinforcement System.

The External Reinforcement System refers to a system that has been designed to support stress that occurs due to the hydrostatic pressure exerted on the outer part of the tank.

The minimized use of reinforcing materials inside the tank, Hi Tank provides perfect hygiene and convenience of easy cleaning for customers.

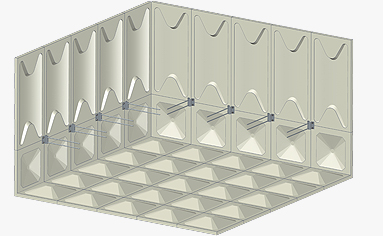

External Reinforcement System at 1~3mH

Sectional view of the inside at 1mH

Sectional view of the inside at 2mH

Sectional view of the inside at 3mH

5-2. Variety of Reinforcement Methods

SERIM

HI TANK

Combined Reinforcement System

01 Air-Vent(ABS)

With PE-mesh insect-guard

02 Water tightness

Maintains perfect water tightness by using sealing tape of PVC foam which is excellent for inhibiting the effects of weathering and for its restorative ability.

03 Outstanding Thermal Effect

Prevents freezing and dew condensation as it demonstrates outstanding thermal effect due to the inherent thermal resistance of the GRP material and polyurethane heat-insulating materials.

04 Level Adjustable Foundation

Replaces concrete foundation

Allows to make easy and speedy construction

Allows to adjust a very fine tolerance

05 External Ladder

Aluminum

06 Manhole

Convenient & close structure

Mounted special lock

07 Internal Ladder

UPVC

08 Lower Water-discharging Panel Structure at the Bottom Area

Uses lowered drainage panel on the bottom so that it can collect and discharge the water.

HI TANK OFFERS

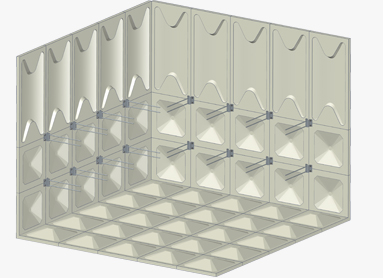

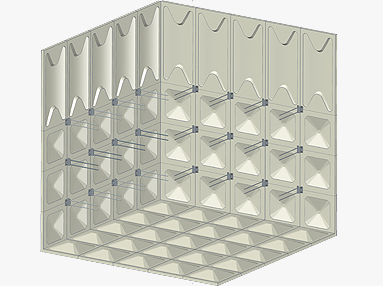

Combined Reinforcement System.

Combined reinforcement system means a system designed to support pressure caused by hydrostatic pressure applied inside and outside the tank.

Combined reinforcement system is a system developed for high-level tanks and big tanks.

As a substantial action for preventing corrosion due to chlorine gas, the air area is designed without any internal reinforcing materials.

External Reinforcement System at 3~5mH

Sectional view of the inside at 3mH

Sectional view of the inside at 4mH

Sectional view of the inside at 5mH

6. Partition, Free Design

Characteristics

Can be installed in Maximum Capacity of a Same-Sized Place

When installing tanks for different usage in a narrow space such as underground rooms and partition, it can be installed for the maximum capacity.

Diversification of Usage

By installing partitions, you can use one tank for drinking and the other tank for other purposes(e.g. fire hydrant, etc.)

Easy Maintenance

As two tanks are installed in one-piece, it is easy to maintain the tank. Even during cleaning, suspension of water supply can be avoided owing to use of compartments.

Low Price

Compared with installing each tank for a different usage, the entire prices including installation expenses are lower.

Installation Example

Front view of the partition

Rear view of the partition

! Since partition panels receive repetitive loads from both the front and back, when installing the panels that are under water pressure, we use the same designed panel that are used for the bottom panels.

Also, a compartment tank is structurally safe due to the fact that the bottom part and the ceiling part are mutually connected and fixed onto partition.

Free Capacity Design

The tank is suitable for large-sized underground reservoirs as its structure utilizes horizontal and vertical spaces at the maximum through the use of diverse sizes of panels.

| Allowable height for installation of the tank | Allowable capacity for installation of the tank |

|---|---|

| 1.0~5.0m height | 1~5,000tons (A tank with a capacity exceeding 5,000tons may be installed through individual design) |

General square type

L-shape type

Center-vacant square type

Rectangular-shape type

C-shape type

※ The corner-usage type system creates maintenance space due to the fact that the tank is installed apart from the pillar, regardless of the location of the pillar.

※ When installing the tank through lining-processing with FRP, if the pillar takes the role of a wall, it may cause inferiority in the structure intensity of the body and the reinforcement system.

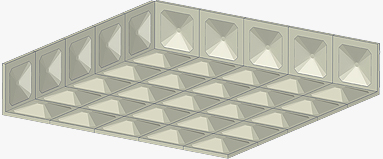

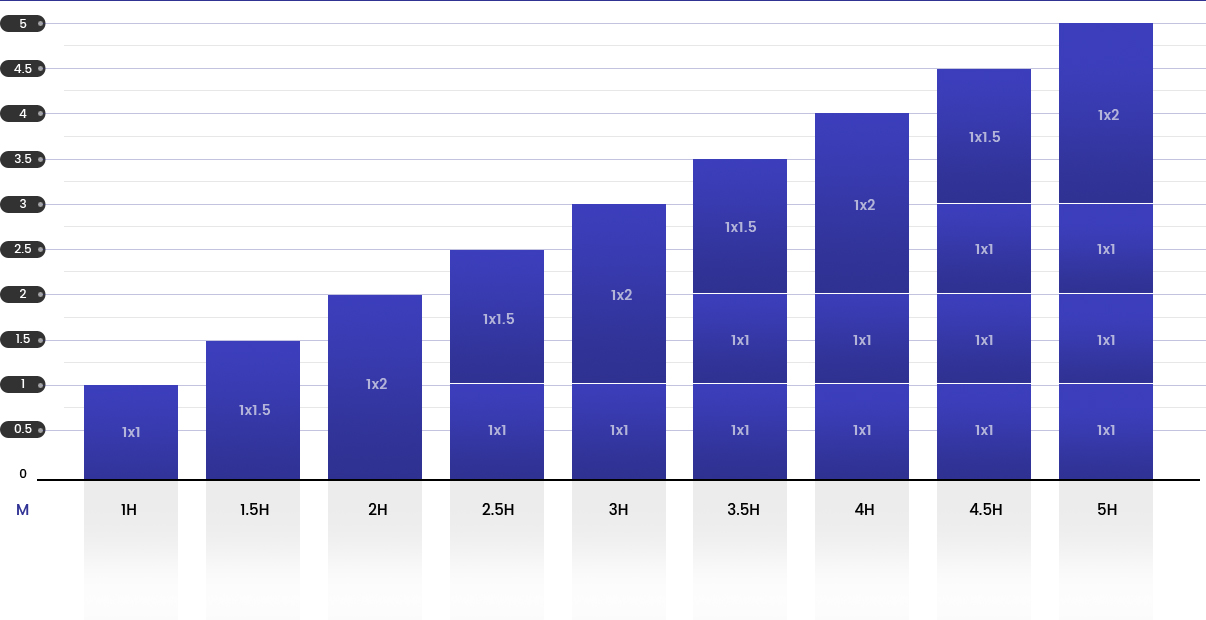

7. Panel Composition

It is a base pad, comprising a rotating steel support with adjustable height and upper and lower support plates, of a systematized water tank that fixes the ends of both bases with a connecting rod.

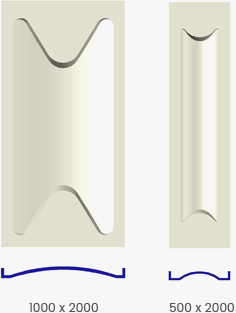

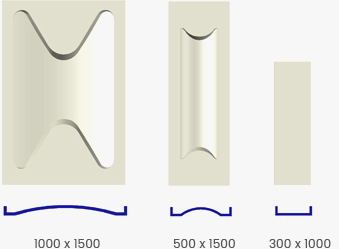

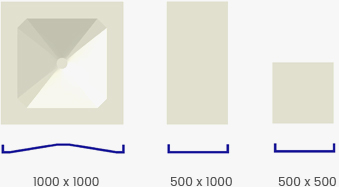

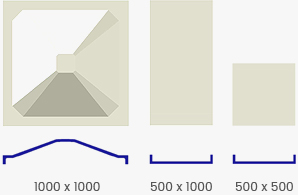

Side Panel Composition Standards by Height

Types and Shapes

Side panel

Side panel

Side panel

Bottom panel

Celling panel

Drainage panel / Manhole panel

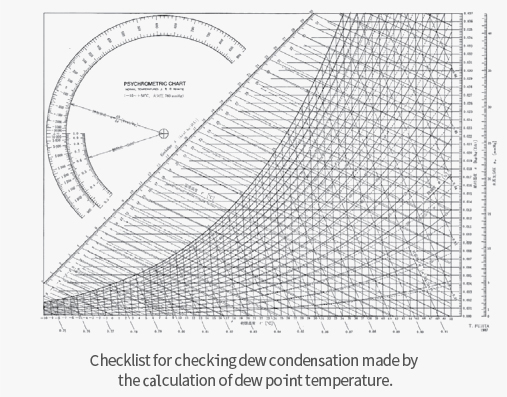

8. Thermal Effect

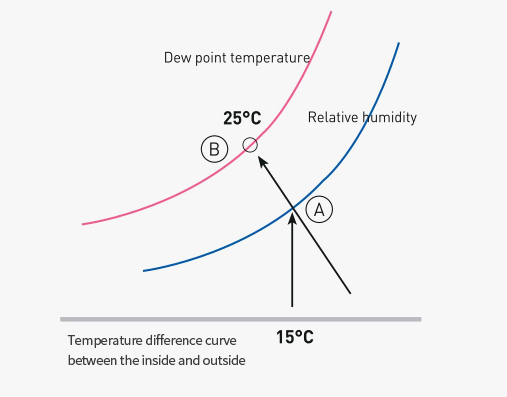

Technical Help

To prevent dew condensation in the water tank

To check the dew condensation in the tank, identify the difference between the inside of water temperature and the outside of tank temperature. Draw a line vertically at the point and mark the point (A) where the line meets the curve representing the relative humidity inside the tank. Draw an oblique line to the dew point temperature curve and mark it contact point (B). Point (B) is the dew point temperature that dew condensation may occur.

Occurrence of dew condensation

- Dew point temperature < the temperature inside the tank : Dew condensation does not occur.

- Dew point temperature > the temperature inside the tank : Dew condensation occurs.

Handling of dew condensation

It is important to lower the relative humidity in the tank.

It is important to complement the ventilation/duct system for the size of the tank.

9. Piping Fitting Specifications

Sizes of panels and locations on which they can be affixed

| Category | Panel Dimension | Fitting Specification | No. of Locations | Affixed Location |

|---|---|---|---|---|

| Side Panel | 1000x2000 | up to 200A | 2 | Upper, lower |

| 500x2000 | up to 150A | 2 | Upper, lower | |

| 1000x1300 | up to 125A | 4 | corner | |

| 500x1300 | up to 125A | 2 | Upper, lower | |

| 1000x1000 | up to 100A | 4 | corner | |

| 500x500 | up to 300A | 2 | Whole face | |

| Exclusive Panel | 500x1000 | up to 300A | 1 | Whole face |

Exclusive panels for fitting (500x1000) are flat, pattern-less plates used for designing with freedom when setting the attachment height of water outlet pipes, alimentary canals, etc.

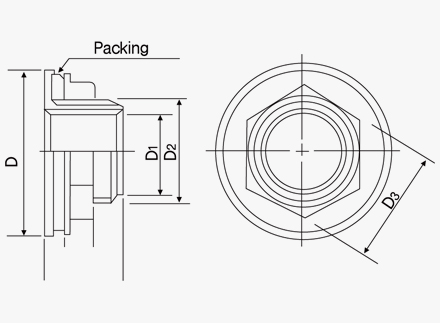

Type and Size of the Fittings

Socket-type

| D | D1 | D2 | D3 | |

|---|---|---|---|---|

| 20A | 55 | 33.5 | 21.4 | 38 |

| 25A | 65 | 40 | 30.3 | 46 |

| 30A | 79 | 49 | 39 | 55 |

| 40A | 85 | 55 | 45 | 61 |

| 50A | 98 | 66.5 | 56.7 | 72 |

| 65A | 120 | 84 | 72.2 | 93 |

| 75A | 132 | 97 | 85 | 105 |

| 100A | 170 | 120 | 110 | 127 |

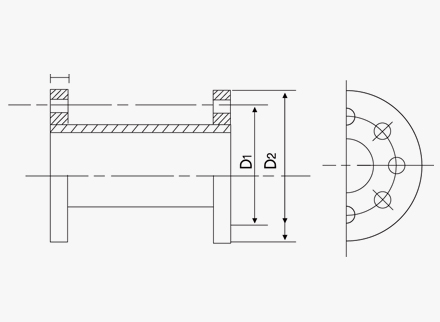

Flange-type

| D1 | D2 | |

|---|---|---|

| 65A | 140 | 175 |

| 80A | 150 | 185 |

| 100A | 175 | 210 |

| 125A | 210 | 250 |

| 150A | 240 | 280 |

| 200A | 290 | 330 |

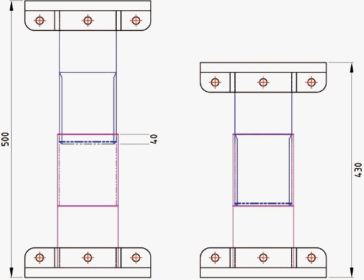

10. Analysis of Dry Pad Structure

What is SERIM HI-FOUNDATION?

It is a foundation of a systemized water tank which consists of a steel support with adjustable rotary height, a top and a bottom plate and both ends are fixed as a linkage for each foundation.

Structure Analysis Flowchart

| Description | Concrete Foundation | Hi-Foundation |

|---|---|---|

| Shape |  |

|

| Pad material | Plain concrete + Steel liner | STS pipe + SMC |

| Build | Moulding-Concrete pouring -Curing-Mortar plaster-Curing |

Bolt assembling |

| Leveling | Poor horizontality (Non-precise standing of skid base) |

Precise horizontality (Precise standing of skid base) |

| Durability (Strength) |

Good compression strength, but instabilities for curing, plastering & liner |

Standardized Uniform Quality with more than 8times safety ratio (Ready made product) |

| Corrosion resistance |

Rust on steel liner Concrete corrosion |

No rust (Anti corrosion material) |

| Pad weight reduction / 300 places |

165,600kg (100%) | 3,600kg (2%) |

| Build time / 500 tons |

More than 30days | Less than 3days |

Structural design and stability verification

SERIM HI-FOUNDATION is a proven product that has undergone a field test for a scientific design and compressive strength test by FEM and a 7 meter high water tank.

FEM analysis result

| HI-FOUNDATION generation stress | |

|---|---|

| Stiffener(Steel) | 197kgf/cm2 < 1600kgf/cm2 (Allowance rate 8.1 times) |

| Stiffener Plate(SMC) | 17kgf/cm2 < 212kgf/cm2 (Design Margin 12.5 times) |

Field Test

| HI-FOUNDATION generation stress |

Base frame strain | Spec |

|---|---|---|

| 7mh | 1.25mm | 10.0mm Below |

| Maximum deformation amount 1.25mm (8 times deformation safety) |

||

SERIM HI-FOUNDATION Prefabricatd Structure

Facebook

Facebook